Standing Seam Combines elegance with reliability.

If Standing Seam were a car, it would be a Bentley.

What is standing seam?

Standing Seam was developed in the 1960’s as an alternative to asphalt, tile, and slate.

The term is in reference to the vertical connections, or seams, between the panels that are created by folding and crimping the edges.

It requires minimal maintenance and has great longevity, making it a superb choice for residential and commercial roofing projects alike.

Features:

Hidden fasteners

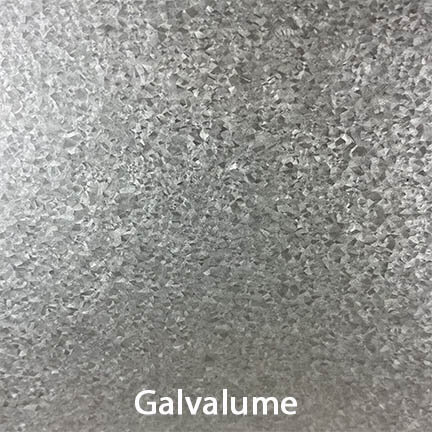

26 & 24 gauge Galvalume substrates available

SMP or PVDF paint by Sherwin Williams and/or Kynar

Roll formed & cut-to-length

We have several different options.

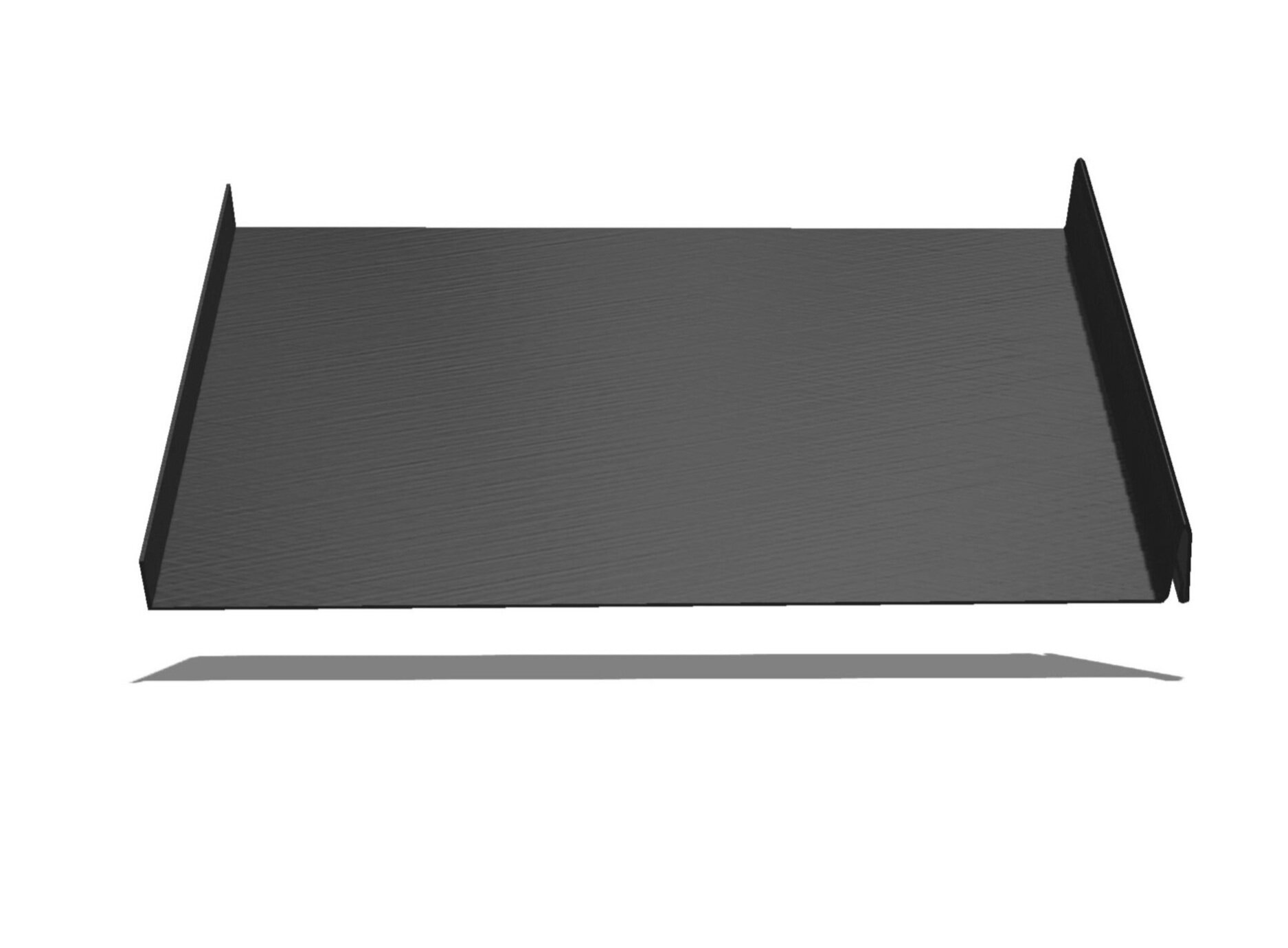

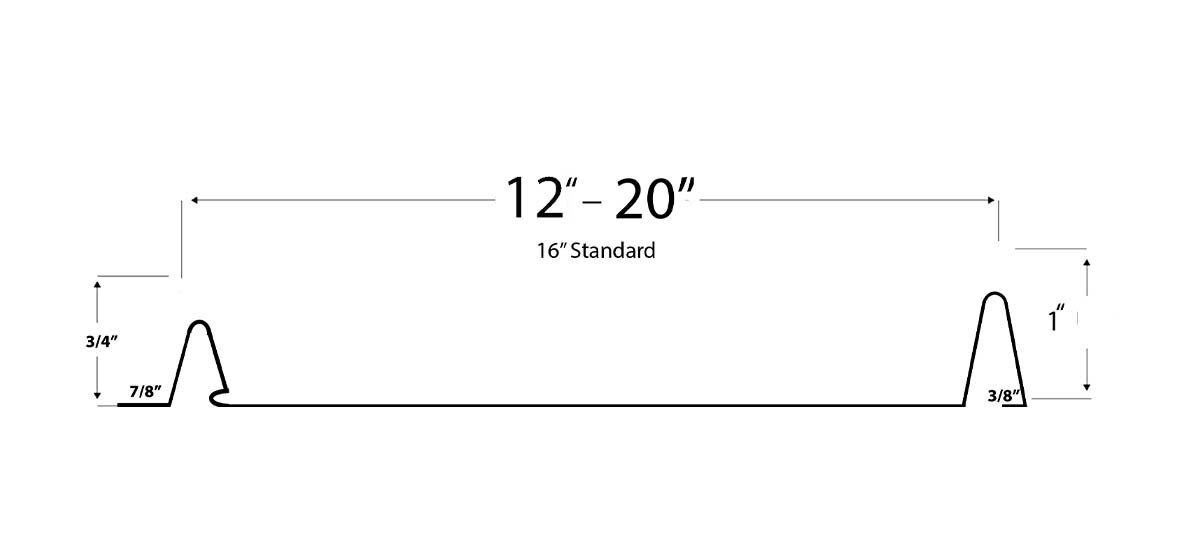

1” Snap Lock

details:

26 & 24 gauge material available

Available in SMP or Fluropon(PVDF) paint system

Hidden fasteners

No clips required for installation

Very rigid and sturdy

Great for residential

Easy to install

Striations or pencil ribs available to help reduce oil canning

Can be installed down to a 1/12 pitch using purlin spacing of 12”

16” wide panel is most common

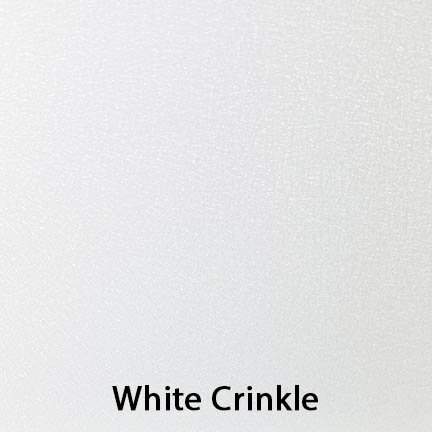

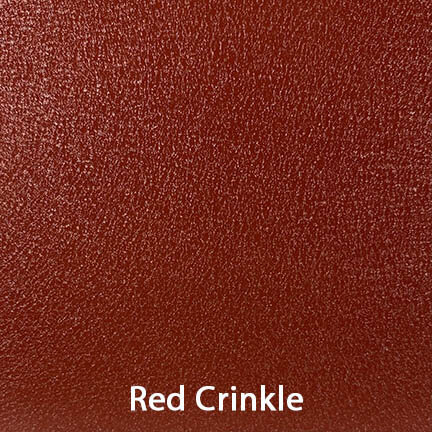

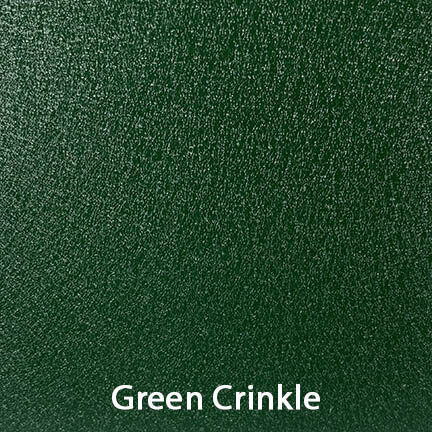

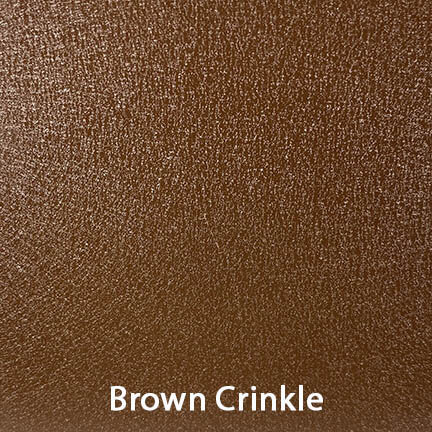

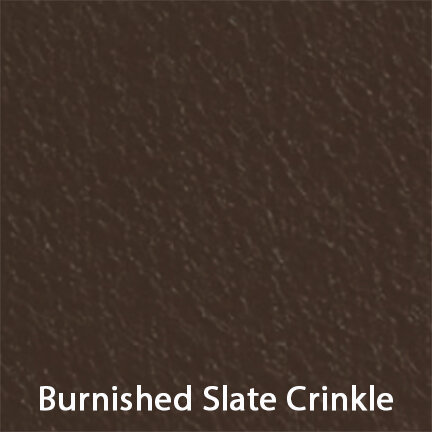

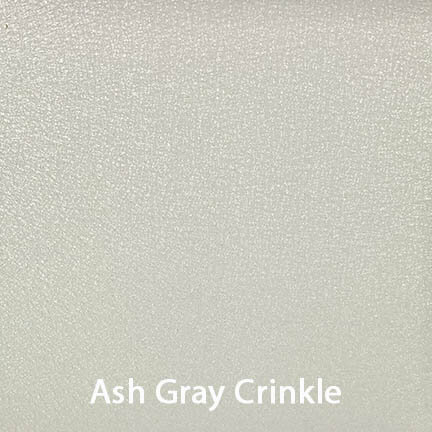

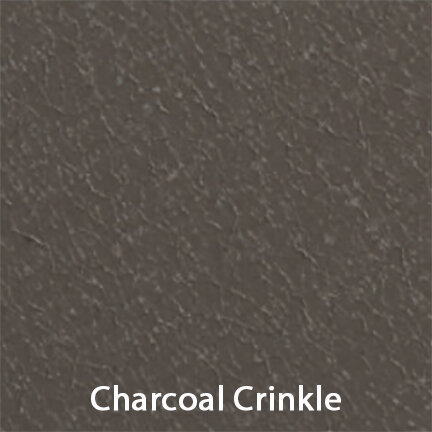

Crinkle finish paint helps mask oil canning

Hybrid system available(combo of hidden & exposed fasteners)

***Call or stop by to speak with one of our sales associates for more information

Gallery Coming soon…

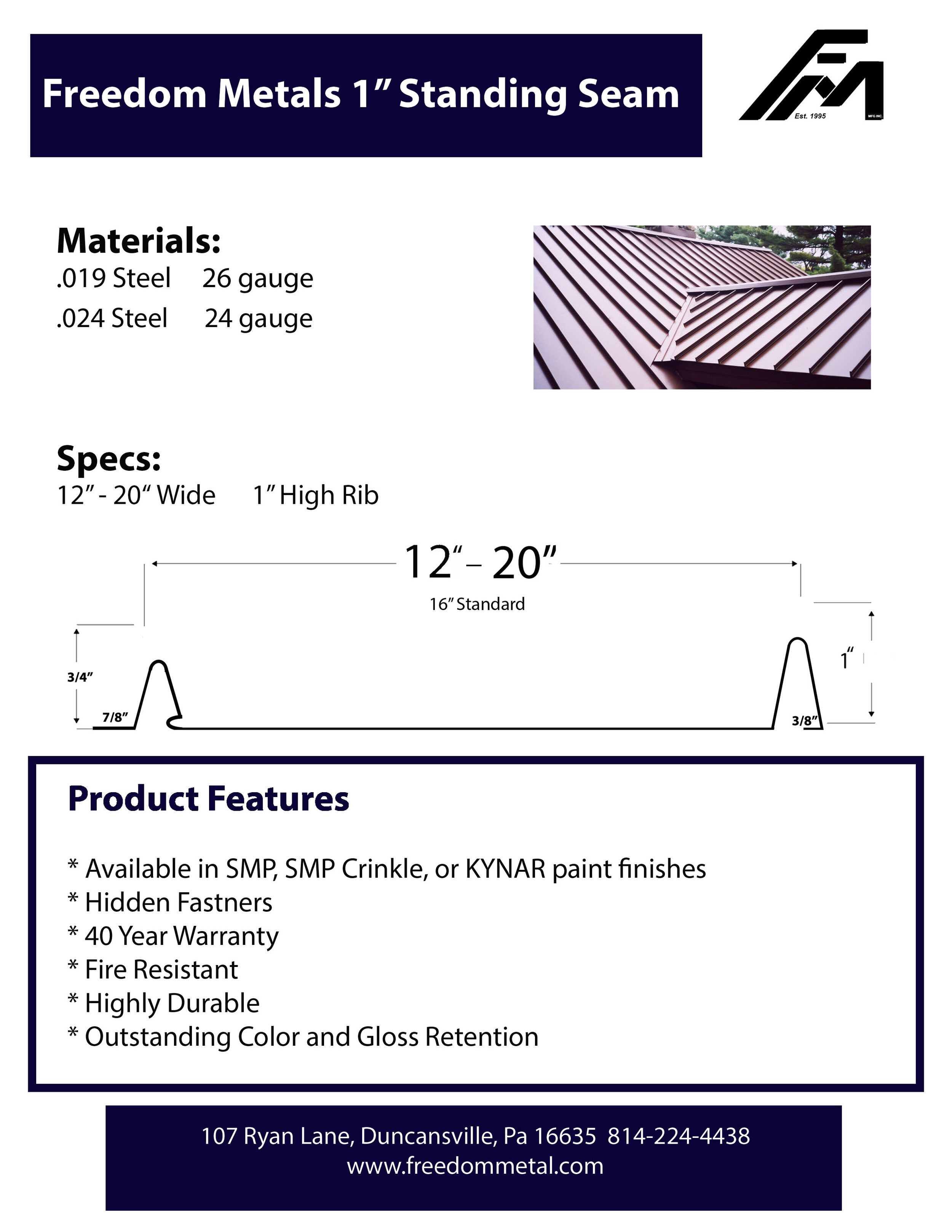

Spec Sheets

1.5” Snap Lock

Details:

26 & 24 gauge material available

Available in SMP or Fluropon(PVDF) paint system

Hidden fasteners

Unlike 1”, clips are required for installation

Ideal for using the S5 clamping system for snow retention and solar panels

Striations or pencil ribs available to help reduce oil canning

Recommend installing on a 2/12 pitch or greater for best results

Recommend installing over solid deck of 7/8” min. thickness

16” wide panel is most common

Crinkle finish paint helps mask oil canning

***Call or stop by to speak with one of our sales associates for more information

Spec Sheets

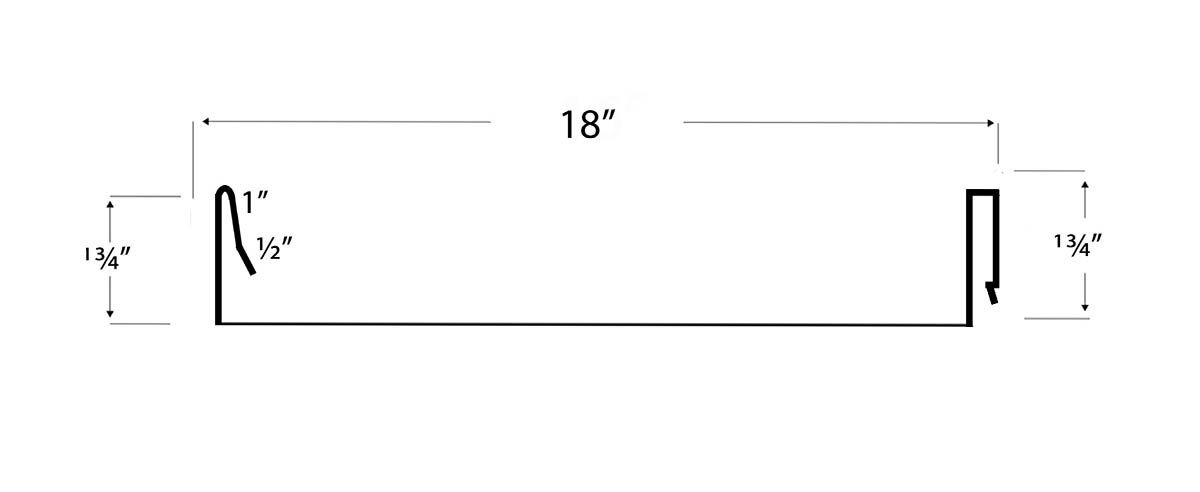

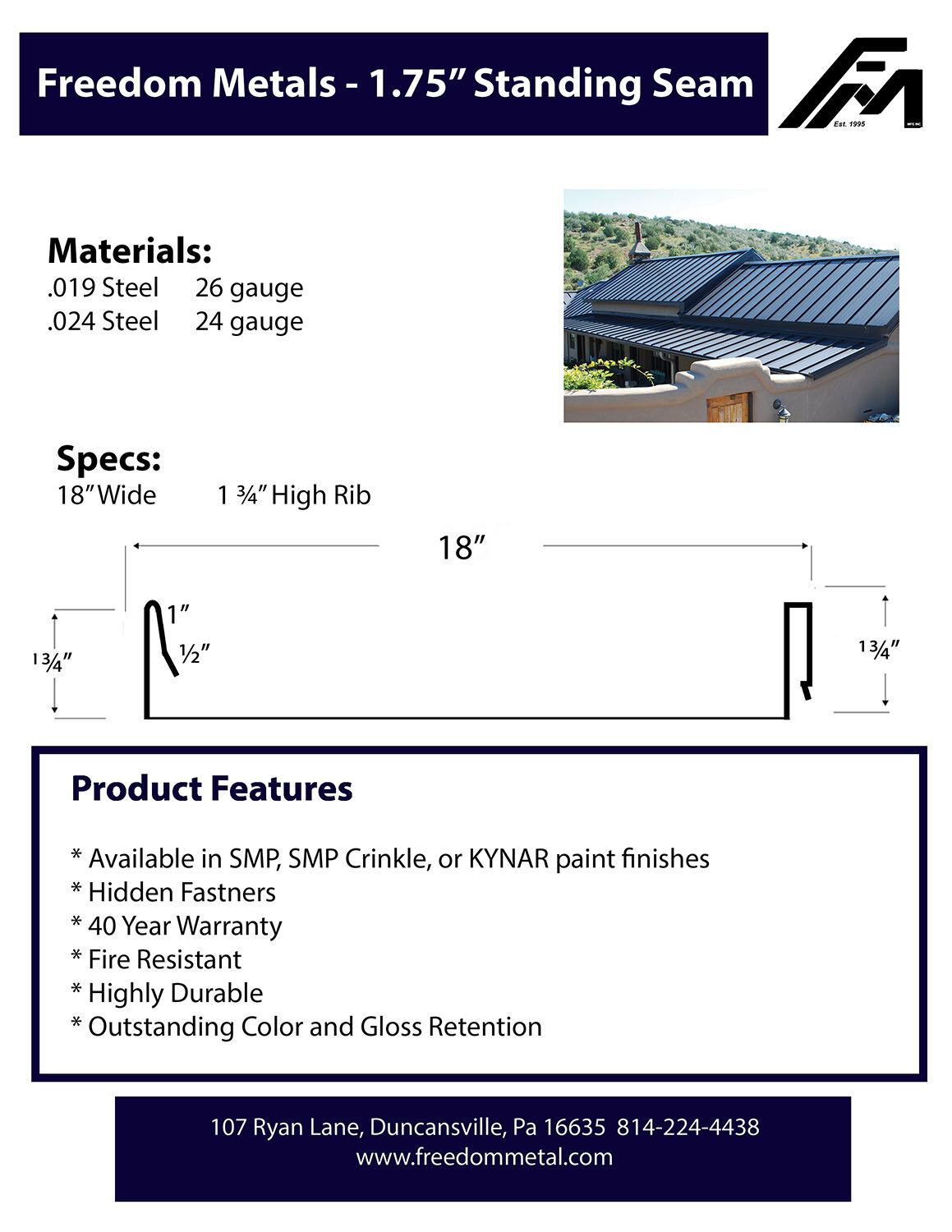

1.75” Snap Lock

Details:

Available in 24 gauge only

Available in Galvalume or Fluropon(PVDF) paint system only

Hidden fasteners

Like 1.5”, clips are required for installation

Taller rib offers a more structurally sound panel

Ideal for installing in areas prone to strong winds or needing to span a wider purlin distance

Can be installed over solid surface or purlin spacing up to 4’

Suitable of 1/12 pitch or greater

Striations or pencil ribs available to help reduce oil canning

18” wide panel

***Call or stop by to speak with one of our sales associates for more information

Spec Sheets

What We Recommend

Well it all depends…

Depending on the type of project you are working on, the style you are looking to achieve, and/or your needs and wants.

For example:

If you are a “do-it-yourselfer” looking to put standing seam on your own house with little experience, we would suggest a 26 gauge, 1” snap lock with a textured paint.

Conversely:

If you are looking to cover a commercial building we may recommend a 24 gauge, 1.75” rib with clips.

***Do to the complexity of standing seam, its usually best to call or stop by and let us go over your specific project with you. That gives us the best chance to fill your needs.

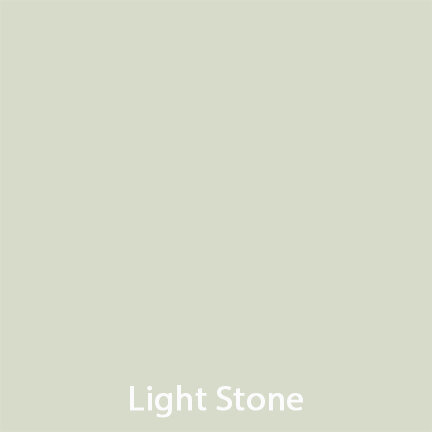

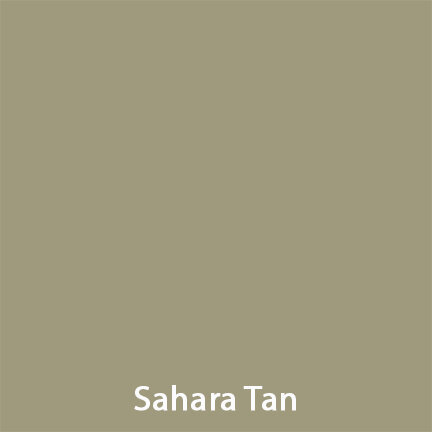

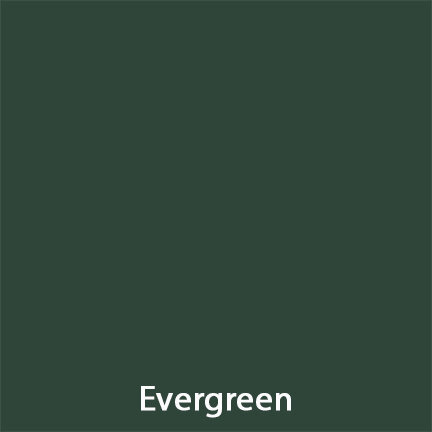

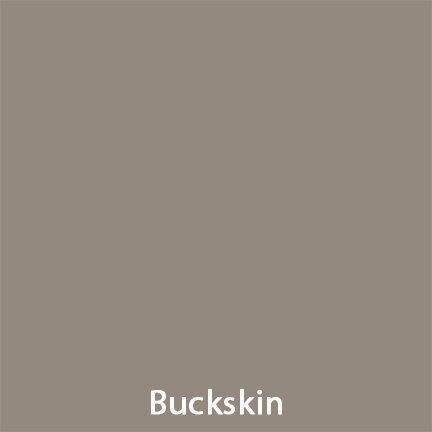

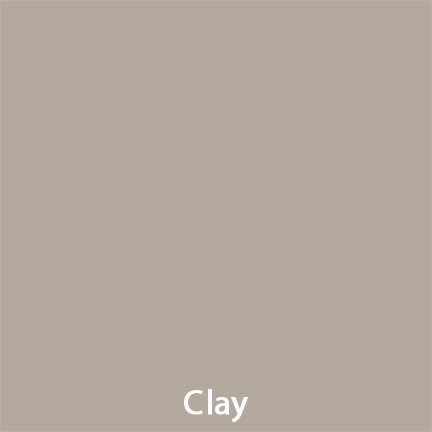

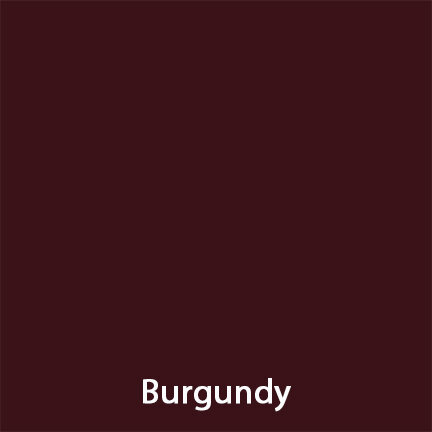

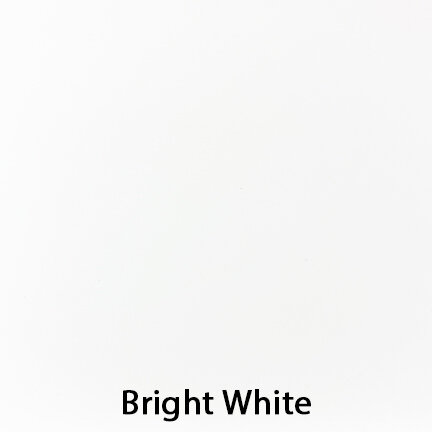

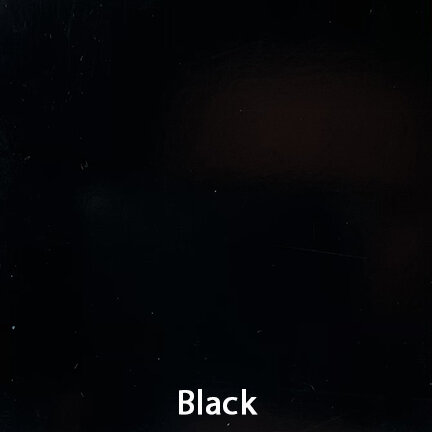

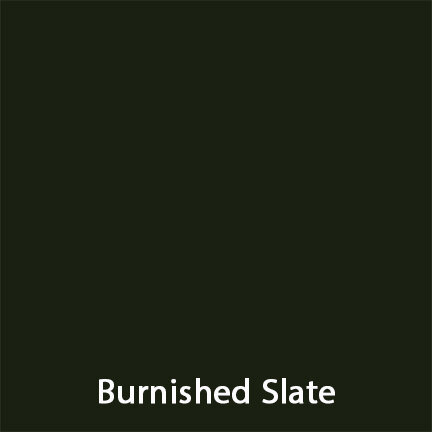

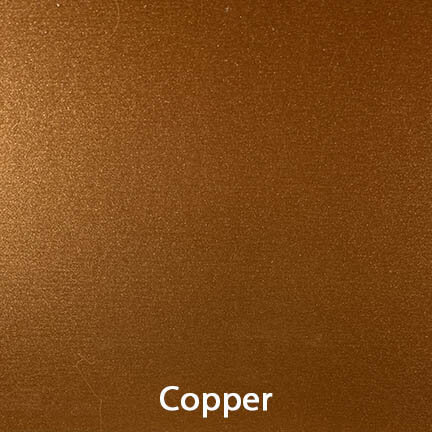

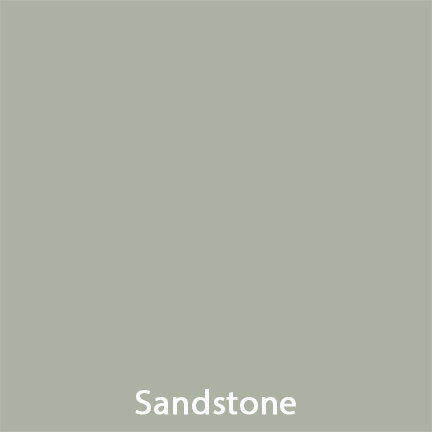

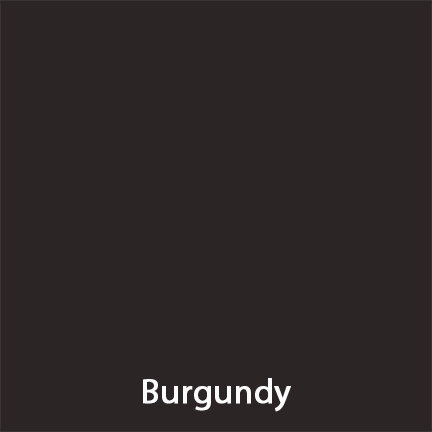

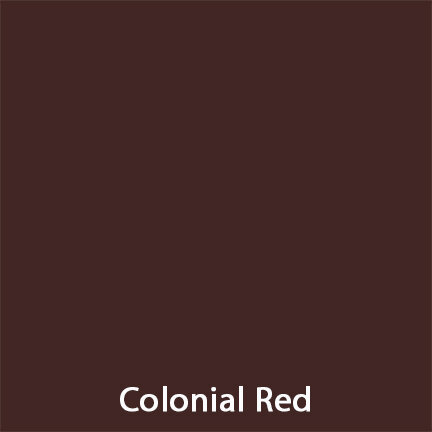

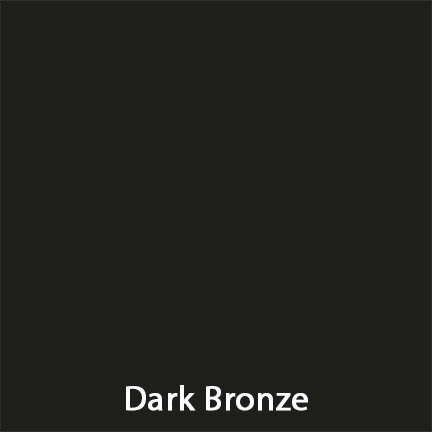

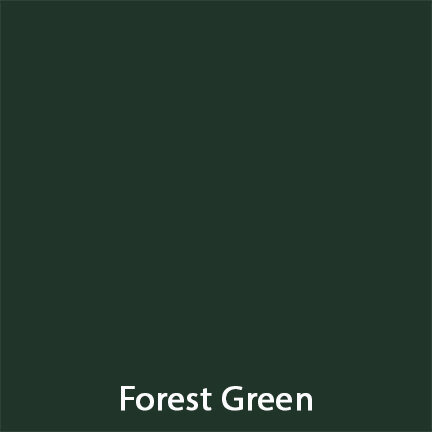

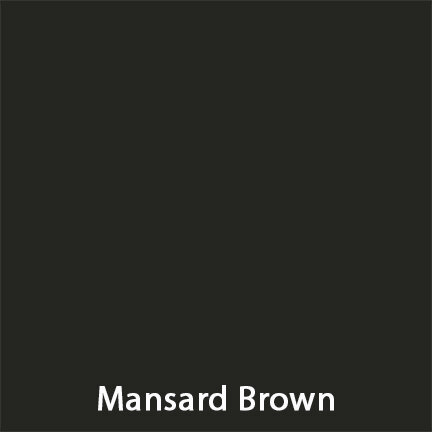

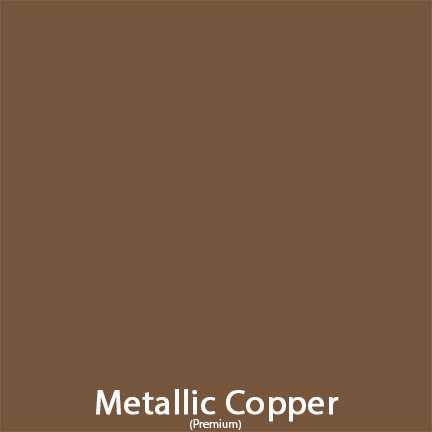

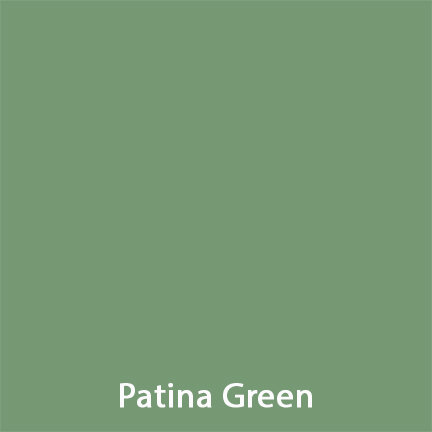

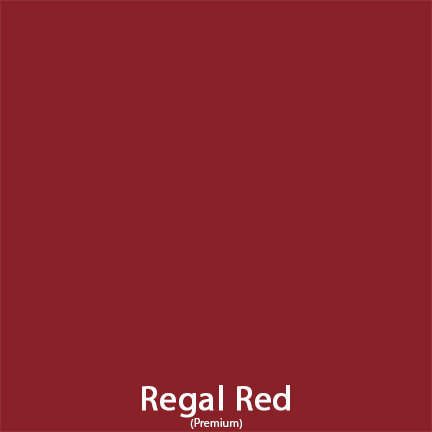

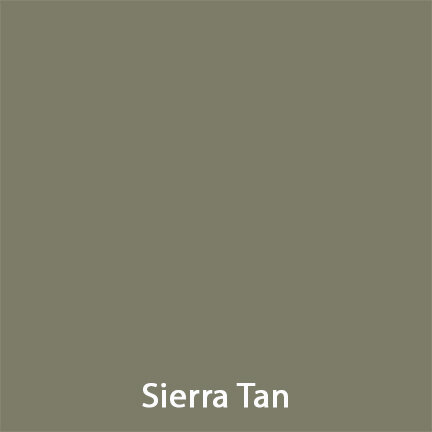

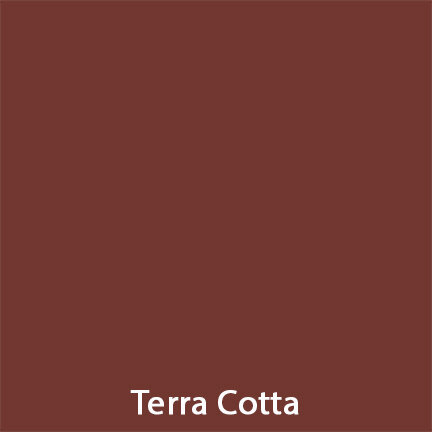

26 gauge colors

AkzoNobel - 30 Year

10 Year