What is the best metal roof for residential housing?

This is a rather simple question, with a not so simple answer.

There is definitely more than one correct answer, and they are without a doubt subjective.

First of all, to be clear -- if budget is not an issue, and you favor a particular style, then by all means choose that style.

At the end-of-the-day, all metal roofing styles a very good, and there isn't a bad choice.

So, for the purposes of this article, and to avoid writing 10 pages worth of content, we are going to set a few parameters.

We are going to tell you what WE think is the best metal roofing choice for residential housing. Specifically for homeowners that fit the following criteria:

1. Have very little knowledge of metal roofing.

2. Are operating on a low to mid range budget.

3. Want the best bang for their buck.

4. Want high performance and longevity, but also style and curb appeal.

Several times a week, we welcome customers into our show room eager to learn about metal roofing. We get asked questions like: What should they buy? Why should they buy it? What their different options are? What's the best? Etc.

We take our time with every single customer no matter how many times we have said the same thing.

We outline their options for color, style, screws, accessories, and types of paint.

We laugh. We learn. We do lots of fist bumps. It really is a wonderful time. Picture visiting the National History Museum, buuuut only learning about metal.

I digress.

Considering how often we get asked the same questions, we wanted to create a simple and informative piece of content that provides value to customers by helping them establish a baseline understanding of metal roofing.

So without further ado, here is Freedom Metals' metal roofing "starter guide".

The different types of metal roofing is where we are going to start.

There are many different types of metal roofing, but for this article we will focus on four.

Ag panel often gets confused with corrugated (which we will discuss below).

Referred to by many different names in the industry including: corrugated, grand rib, G-rib, ribbed roofing, etc.

The panel is roll formed from a 41.5" wide master coil.

The ribs are nine inches on center creating a 38" wide panel.

You lose two inches of width from overlap, providing 36" of actual coverage.

It has exposed fasteners, and is "cut-to-length."

It comes in a plethora of color options, both textured and smooth paints alike.

Ag panel is rigid, durable, and versatile.

Used for both roofing and siding, and interior or exterior.

Due to its versatility and coverage width, ag panel is the best bang for the buck in metal roofing.

2. Corrugated

Corrugated is the profile that looks like a Ruffles potato chip.

It’s a very old style that was synonymous with old barn roofs.

Typically made from galvanized metal.

Often found with black tar covering it to extend its lifespan.

Today, corrugated is often confused with ag panel.

Corrugated is no longer the prefered choice for residential roofing, because ag panel has surpassed it in terms of durability, performance, and aesthetics.

Today, corrugated metal is most often found inside in bars, restaurants, and houses on accent walls, bar backings, and backsplashes.

Standing seam is the premier product in metal roofing.

It has hidden fasteners and better paint than ag panel.

The style is very different from ag panel, and gives your house an expensive look.

The ribs are approximately 16" apart offering 16" of coverage.

The only drawback to standing seam is the cost. Standing seam costs on average anywhere from 2 to 3 times the amount of ag panel.

If the hidden fastener look is what you’re after, then your only real choice is standing seam.

There are several different rib profiles available including 1", 1.5", and 1.75". Sometimes 2" or greater are used in commercial roofing applications.

The 1" or 1.5" snap-lock is usually the best choice for residential application.

4. Metal Shingles

Compared to standing seam, metal shingles are very expensive.

Individually, they do not offer much coverage, and are labor-intenstive to install.

They are beautiful, long lasting, and look incredible, but they come with a cost.

So it all comes down to budget and personal style preference.

What type of metal roof should YOU buy?

Imagine this common scenario.

A husband and wife are looking to replace the roof on their home. Money may not be tight, but spending it on a roof isn't the sexist choice.

Usually, the husband is looking for practicality and a bargain. While his wife is looking for style and curb appeal. Due to the many misconceptions about metal roofing, the couple doesn't believe metal offers both solutions.

A common objection we hear is "I don't like the shininess of metal. It makes a house look like a tin can."

I will agree that not all homes look good with a shiny metal roof.

Alas, there is a solution.

Several years ago, Sherwin-Williams came out with a textured paint called Crinkle Finish. There is no shine, and it makes the house look much warmer and less like a barn or a pole building.

When you remove the shine and add the texture you get more of a matte finish that blends with the house.

This also solves one of the common complaints we hear, which is "metal roofing looks cheap". I promise, when you put a Crinkle Finish roof on your house, it does not look cheap. It looks expensive and stylish, and changes the entire curb appeal of your home.

Recommendation # 1: Buy a metal roof with a Crinkle Finish paint.

Another common question or concern is about the potential for the screw holes to leak.

This was a serious issue in the past due to the rubber washer that seals the hole. The rubber washer is exposed to the elements and over time can deteriorate, causing a problem. Now you have a hole in your panel, allowing water to penetrate and cause a leak.

Several years ago, a new screw called Pro-Z, was developed to combat this common problem. The Pro-Z screw has a thicker washer encapsulated by an oversized aluminum cap. When the screw is tightened, the cap bonds to the panel, creating an airtight seal. The washer is no longer exposed to the elements, providing protection against deterioration. Pro-Z's are considered lifetime screws, and are an absolute game changer.

Upgrade to a Pro-Z screw, and eliminate the potential for screw hole leaks.

Recommendation # 2: Use Pro-Z screws to fasten your metal roof.

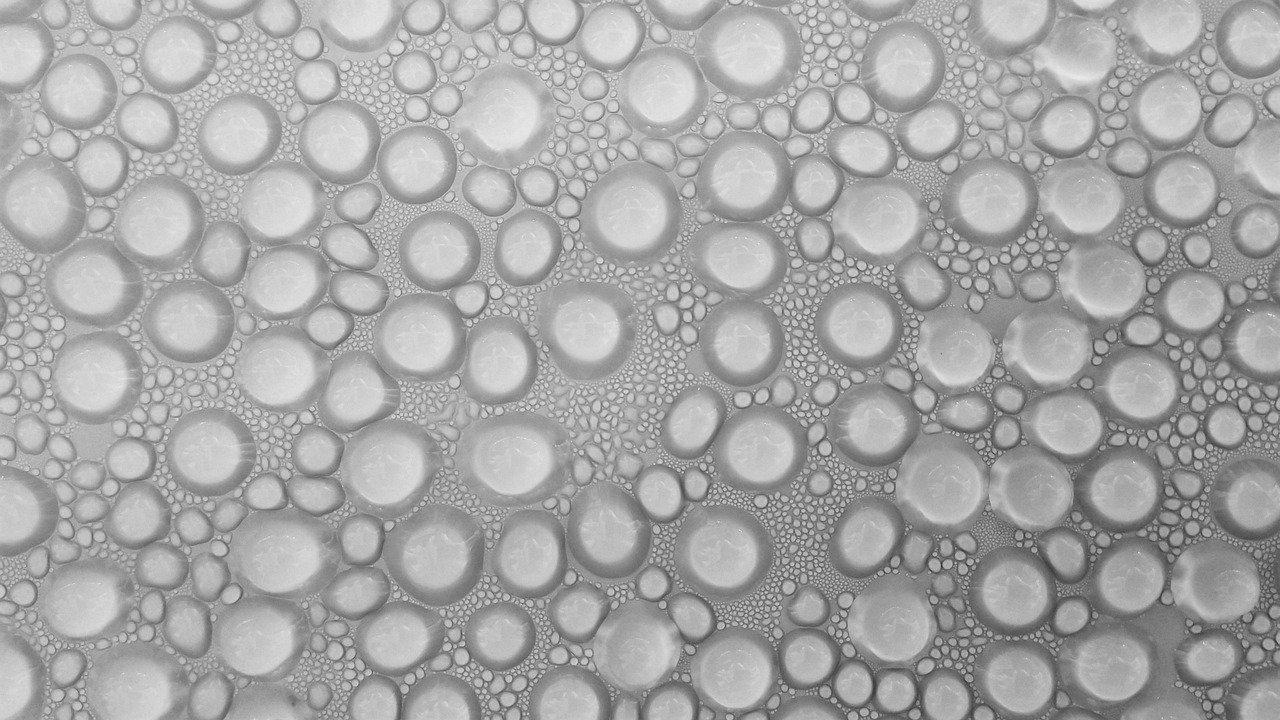

The third common question we get asked is about condensation and leaking issues.

If you’re interested in learning more about condensation under metal roofing, we have a detailed blog post addressing this very issue.

Condensation under metal roofing is a real concern. If your house is not properly insulated, there is a strong possibility of it happening. External leaks tend to stem from installation errors.

There are several ways to mitigate these problems, beginning with a good installer.

Aside from that, avoiding "corner cutting" is the next best thing. We recommend installing FanFold insulation and an ice and water shield under your metal roofing panels.

If you combine those two things, Pro-Z screws, and an above-average installer, the chances of your roof leaking will be minimal.

Recommendation # 3: Install FanFold insulation and an ice and water shield under your metal roofing panels.

Another common topic we discuss with our customers is ventilation.

You want to allow your roof to breathe without allowing birds, bugs, and debris from flying in.

There are several products on the market that do this, but the two best in our opinion are FloVent and FastVent. They are the industry leaders in foam closure strips, and offer the best combination of longevity and durability.

Recommendation # 4: Use FloVent or FastVent under your ridge cap to allow ventilation while also preventing birds, bugs, and debris from flying in.

Finally, an added benefit of installing a metal roof is that you don’t have to remove the existing shingles. Pending no structural damage, the existing roof deck acts as a vapor barrier, and a solid foundation to install on.

This is a huge benefit and a cost reduction because there is little to no demo when installing the new roof.

Having said that, you shouldn't install the metal panels directly on the roof deck, so what do you do?

Common practice is to first secure furring strips onto the existing roof deck. Then, screw your metal panels onto them. A furring strip is either a 1" x 3" or a 1" x 4" dry wooden board. They are usually 8' to 12' in length, and should lie perpendicular to the roofing panels.

Some installers prefer to nail their furring strips to the roof deck on account of speed. We recommend using a 3" star drive deck screw for ultimate security from wind and storms.

Recommendation # 5: Install metal roofing panels over top a 1" x 3" or a 1" x 4" furring strip secured to the existing roof deck. Secure your furring strips using a 3" star drive deck screw for ultimate protection from wind.

Following these five recommendations when purchasing your metal roof will mitigate potential risks.

The upfront cost will be higher compared to slapping on a few bare bone metal roofing panels, but the payoff will be worth it.

To recap:

Condensation and leaking are substantially reduced with Pro-Z screws and FanFold insulation.

A textured paint like WeatherXL Crinkle Finish by Sherwin Williams will give your home amazing curb appeal and prevent it from looking cold and unwelcoming.

Do not remove the existing shingle roof before installation. Rather, secure wooden furring strips to the existing roof deck using 3" star drive deck screws. Then attach the new metal roofing panels to the secured furring strips. This will protect against heavy winds and storms.

If you follow our recommendations, you will end up with a beautiful and dependable roof.

A roof that will last.

A roof that will raise the value of your home.

A roof that will be a great selling point if you ever sell your house.

Thank you for reading! Please check out the rest of our site!